True Frequency Technology®

Profile sorting through True Frequency Technology®

True Frequency Technology® is a high level Raw Shaft Sorting Program. It’s main function is to simplify and define the overall ‘True Frequency’ of a full set of raw uncut shafts. This in turn will result in a refined ‘True Frequency’ profiled set of golf clubs.

Raw shaft data is compiled in 5″ beam length increments incorporating butt, mid, and tip frequency (B-M-T) measurements.

The TFT program is able to compile charts for both irons and wood shafts.

The TFT sort engine automatically defines and assigns a TFT stiffness value. The program then sorts and then reorders the raw shaft data by the overall stiffness. Sorted data is then plotted in a graphical format for a quick visualisation.

True Frequency Technology® rates the resultant data by classifications from ‘Class A’ to ‘Class E’.

Class A – a very good set of raw shafts.

Class E – a poor set of raw shafts that will still work well once the TFT sort is complete.

To get a “Class A” set can be difficult due to manufacturing tolerances and variability. Regardless of the final sort classification, you can be sure you will have a far superior set than that of a random build.

A ‘Class A’ set of shafts will have very little variation shaft to shaft. To reduce the variation simply measure just a few extra shafts, then eliminate and replace those shafts. Naturally the tighter the overall raw TFT profile, the tighter the assembled frequency will be.

Even a ‘Class E’ set of shafts will still produce a great set of clubs, thanks to True Frequency Technology®. If this ‘Class E’ set of shafts were not sorted, then the resultant the play-ability would be inconsistent at best.

The True Frequency Technology® sorted graphs will display each 5 inch beam length and its calculated TFT Value. Adhering to a 4 or 4.33 CPM rate of change should not apply to all shafts. Different shaft manufacturers have different intents. True Frequency Technology®, when combined with the TLT tipping increment will allow a constant butt to last step pattern. By maintaining this pattern the shafts intended design remains intact. This keeps step patterns in line relative to each other, eliminating the unevenness of a “nibbled” set.

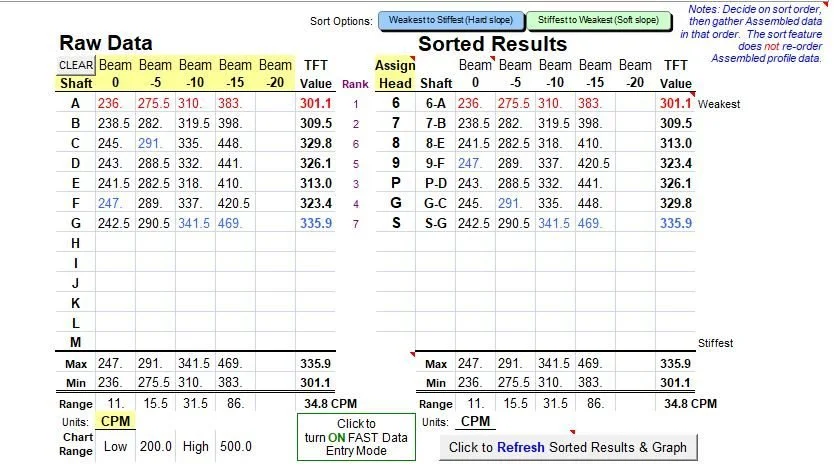

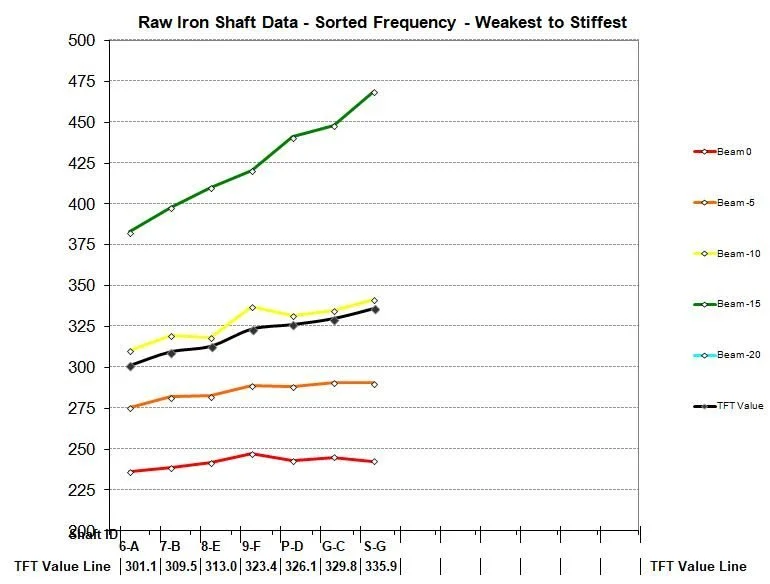

Example 1: Class E set of shafts

Class E

Class E set through the TFT sort engine.

Large variation:

11 CPM range in the butt section Beam 0

15.5 CPM range in the Beam -5

31.5 CPM range in the Beam -10

86 CPM range near the tip section Beam -15

Note the lack of consistency in the cycles per minute (columns) and the excessive ‘Range’ with high ‘Min’ and ‘Max’ values. A very poor set of shafts that would result in a very inconsistent set if built randomly.

If this set of shafts were not sorted – shaft A (weakest) could be in your 7 iron and shaft G (stiffest) could end up in your 8 iron. These 2 clubs would perform and feel quite differently from each other.

Result: poor frequency profile build with grave play-ability issues.

How to correct?

First run this set of shafts through the TFT sort engine.

Then install the weakest shaft in the longest iron (shaft A) and the stiffest shaft in the shortest iron (shaft G). This set of shafts have now become far more consistent than what they would have been if installed randomly.

After the sort, this set will play with a decent amount of consistency.

You have increased the value of the shafts and optimised them for a greatly improved play-ability.

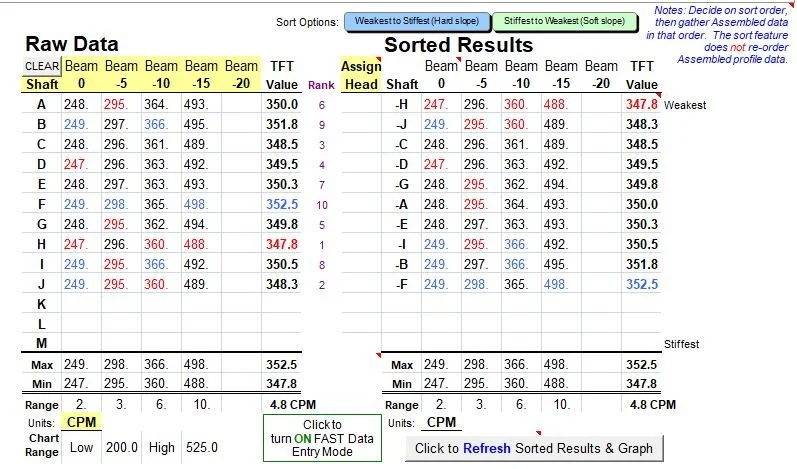

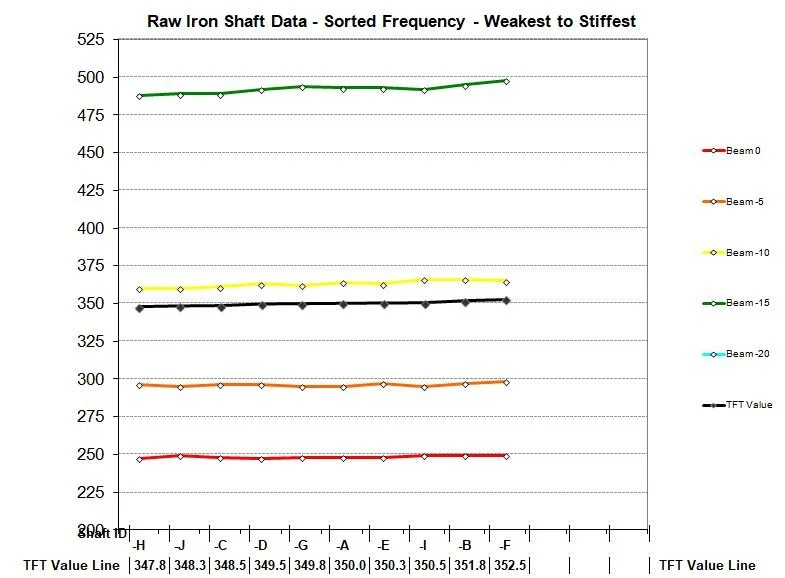

Example 2: Class A set of shafts

Class A

Class A set through the TFT sort engine.

Note how small the range of this Class A set of shafts is:

2 CPM range in the butt section Beam 0

3 CPM range in the Beam -5

6 CPM range in the Beam -10

10 CPM range near the tip section Beam -15

This is a great set of raw shafts driving consistency into the completed set.

Result: This is a set of shafts you want for your premium build with a very tight frequency profile.

Comparison

Note the near flat line cycles per minute, indicating very little variation shaft to shaft.

Note the consistency in the cycles per minute (columns) and the greatly reduced ‘Range’. Overall maintaining very tight ‘Min’ and ‘Max’ values.

Benefits of True Frequency Technology® sorted shafts:

A perfect slope or curve is simply not attainable – by any system. Keep in mind that most golfers have a tough time detecting a 1/3rd of a flex (approximately 3 CPM), where True Frequency Technology® should keep you well within this limit.

The final True Frequency Technology® slope is the key factor in greater consistency being built into your set.

The TFT sort engine has far exceeded any butt frequency sort and has established a perfect base line to build with unparalleled consistency.